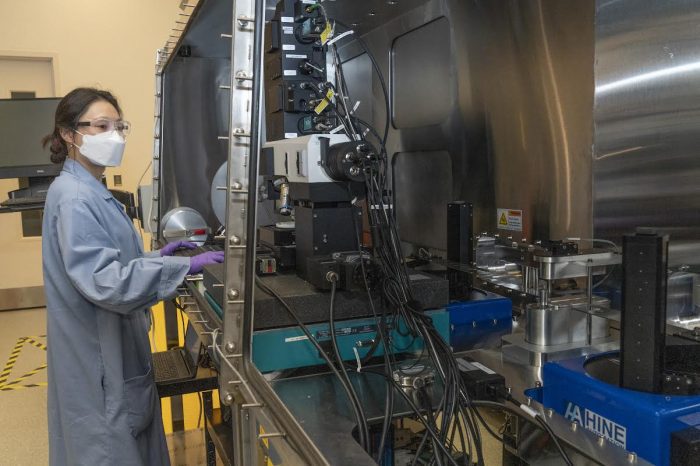

BNL’s Suji Park creates 2D nanotechnology efficiencies at the QPress

By Daniel Dunaief

Technological advances, like the audiences who crave the latest gadgets and gizmos, often proceed with a sense of purpose and speed. Anything that gets in the way or slows down the process can become an obstacle to overcome.

And so it is for Suji Park, a member of the Research Staff at the Center for Functional Nanomaterials at Brookhaven National Laboratory. Park, who joined the lab just under four years ago, is helping in the process of creating a reliable and faster process to produce two dimensional objects that could become parts of future nanotechnology.

Unlike an assembly line production to manufacture cars or objects that are part of the visible world, Park is working with scientists from around the world at the QPress, an effort that started a year before she arrived to create miniature materials that could become part of a host of technological advances, including in quantum information systems.

In the three steps involved in stacking two dimensional structures, the QPress system can improve efficiencies.

In the process of exfoliation, scientists typically create monolayers manually, which involves a long training period, time and effort to make two dimensional flakes. With the right recipes, the QPress uses controlled conditions, some of which are beyond the human range, through a more reliable process that takes a few hours of training.

The most time consuming step in the process involves searching for flakes with particular properties. Park uses machine learning techniques to help researchers filter out thin flakes.

The QPress has not automated the stacking of flakes, but they have created a motorized machine they can control remotely.

“We can provide more precise manipulation to stack nanomaterials, which makes this process easier and faster” than a manual or other motorized setup, Park explained.

The manufacturing process was “not very systematically studied. People didn’t know exactly what the important factors were to make good, quality two-dimensional materials.”

One of the earliest parts of the QPress process involved trying to understand how the older methodologies worked.

When Park started to design the exfoliation machine, she said she was “surprised” at how little people knew about the mechanism. Once scientists create flakes they need, they typically move on. At a place like BNL, however, staff scientists can spend time on fundamental studies.

BNL“decided to make a machine to study this process and to make two dimensional materials easier,” which would allow scientists to “spend their time on research and not on the process,” she said.

Like a good baker

Park described the process of making these critical parts as being akin to the way a baker combines ingredients to create a house special bread. She may not have an exact recipe, but combines ingredients and cooks them at a particular temperature to produce the desired product.

“Somebody who knows how to make a good, quality bread has a sense of how it’s done” by relying on intuitive experience, she said. “Human factors are involved.”

A bread machine, by contrast, makes similar quality breads regardless of who uses it, which is more like how the QPress is designed to work to help make quality, reproducible two dimensional materials for application in nanotechnology.

The mechanized QPress process can optimize the steps, control a host of parameters and increase the yield.

To be sure, Park suggested the process isn’t designed to reach mass production levels, which would take another level of investment. Instead, QPress is targeting lab research.

Greater efficiency

You Zhou, Assistant Professor at the University of Maryland, can’t fabricate materials that are chemically unstable or that are air sensitive. He could, however, do so at QPress.

“The QPress system offers better control and reliability than our home-built system,” Zhou said. “Depending on the situation, sometimes we send graduate students to work onsite at the QPress for a week. Other times, we perform experiments remotely. Both have been working well for us.”

The QPress process has created a higher yield, with larger samples that sped up the process of making materials.

Zhou added that the QPress system seems to be one of the most advanced available to researchers in terms of control and automation.

Greater efficiency has meant that his group “has become more productive and can invest their saved time in other research activities,” Zhou said. “The technology is still improving.”

The process

Researchers stack these structures for specific applications. Depending on the sequence and orientation of each layer, the structures can store, process or communicate information.

Park is working with users to discuss experiments in advance. The discussions involve considering the feasibility of creating the materials and structures.

Air sensitive two dimensional materials can degrade over time. BNL prepares flakes one or two days before scientists arrive.

A cataloger can scan a sample and detect mono to tri-layered graphene flakes using a machine based learning program. The QPress group doesn’t make heterostructures. Users need to do it themselves.

With the QPress under development, the user community has continued to build. Last year, the QPress worked with 20 to 30 scientists. The numbers this year are outpacing that demand.

Beginnings

Born and raised in the southern part of South Korea in Masan-si, which is now called Changwon-si, Park liked math and science as a teenager. She thought she’d become a teacher until she was accepted by POSTECH in her second grade of high school. During her undergraduate training, she decided to earn her PhD and become a scientist.

Currently a resident of Coram, Park loves working at the Center for Functional Nanomaterials. Outside of work, she enjoys watching movies, shows, painting, drawing, baking, cooking, and yoga. She recently started growing plants.

In her work, Park, who is one of two dedicated members of the QPress team, appreciates the opportunity to create efficiencies for other scientists.