By Daniel Dunaief

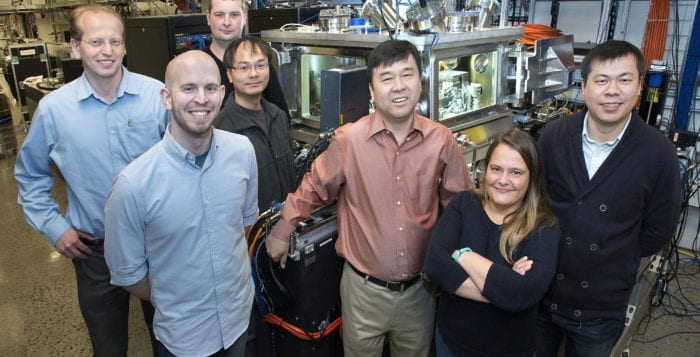

There’s precision in measurements and then there’s the world of Yong Chu. The head of a beamline that’s housed off to the side in a separate, concrete structure from similar efforts at Brookhaven National Laboratory, Chu led the design, construction and commissioning of a sophisticated beamline with a resolution of as low as 3 nanometers, which he hopes will get down to 1 nanometer within a year.

Just as a measure of contrast, a human hair is about 80,000 nanometers wide. Why so fine a resolution? For starters, seeing objects or processes at that high level can offer insights into how they function, how to improve their manufacture or how to counteract the effects of harmful processes.

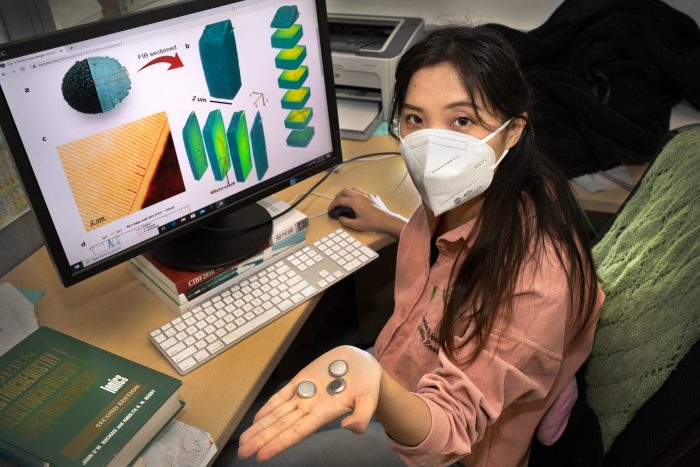

With a battery, for example, the Hard X-ray Nanoprobe, or HXN beamline, could help reveal structural weaknesses in the nanostructure that could cause safety issues. In biology, numerous functions involve sub-cellular organelles that respond to proteins. Proteins are typically smaller than the HXN beamline can image, although researchers can tag the proteins with metals, which allows Chu, his colleagues and visiting scientists to see an aggregate of these proteins.

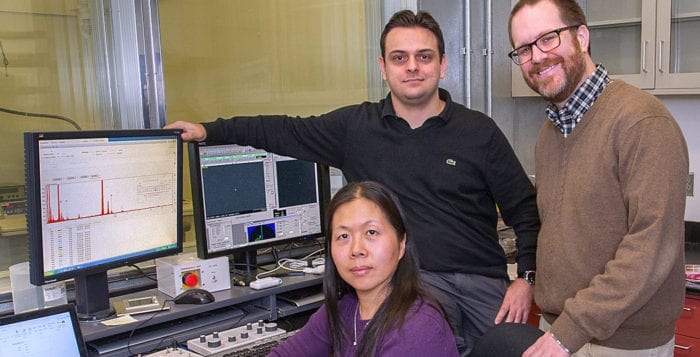

The HXN beamline can also help explore environmental problems, such as how plants transport harmful nanoparticles to their fruits or how artificial compounds absorb nuclear waste. Imaging beamlines that use micro-focused beams typically offer spatial resolution of 10 microns, 1 micron or even 100 nanometers, according to Ryan Tappero, the head scientist at the X-ray Fluorescence Microprobe at BNL, who has used the HXN for his research. Using the NSLS II source properties and a new x-ray optics development routinely offers resolution of 10 nanometers, which pushes the spatial resolution down by another factor of 10, which makes the HXN, according to Tappero, a “game changer.”

Tappero described Chu as a “rock star” and suggested he was an “exceptional beamline scientist” who is “very knowledgeable about X-ray optics.”

BNL houses 19 beamlines at the National Synchrotron Light Source II, a state-of-the-art facility large enough that scientists ride adult tricycles inside it to travel from one beamline to another and to transport supplies around the facility. BNL is building another nine beamlines that it hopes to have operational within the next 18 months. Each of these beamlines offers a different way to explore the world of matter. Some beamlines do not use a focused beam, while others produce beams with high angular or high energy resolution. Imaging beamlines such as the HXN produce a small beam size.

The HXN beamline has the highest spatial resolution of any beamline at the NSLS-II. Scientists building the HXN grew a nanofocusing lens with a dedicated deposition system that was constructed at the NSLS-II Research and Development lab. The system grew a nanofocusing lens a layer at a time, alternating materials and controlling the thickness at better than 1 nanometer, Chu explained.

The beamline where Chu works has padded walls, a door separating it from the rest of the light source and a monitor that records the temperature to the thousandths of a degree. “We are constantly monitoring the temperature around the X-ray microscope and inside of the X-ray microscope chamber,” he said. Around the microscope, he can keep the temperature stable within 0.03 degree Celsius. In the chamber, the scientists maintain the temperature at better than 0.003 degree Celsius.

So, now that Chu and his colleagues built their beamline, have the scientists come? Indeed, the interest in using the HXN has been well above the available time slots. For the three cycles each year, BNL receives about four requests for each available time. This reflects the unique qualities of the instrument, Chu said, adding that he doesn’t expect the rate to drop considerably, even as the HXN continues to operate, because of the ongoing demand.

Researchers have to go through a peer review process, where their ideas are graded for the likelihood of success and for the opportunity to learn from the experiments. All beam time proposals are reviewed by external expert panels, which examine the scientific merit, appropriateness of use of the facility, capability of proposers and quality of prior performance and the research plan and technical feasibility.

Chu fields about 10 calls per month from scientists who want to speak with him about the feasibility of their ideas. He may suggest another station at the NSLS-II or at the Advanced Photon Source at Argonne National Laboratory in Chicago, where he was a beamline scientist starting in 1999.

“I know many of the beamlines” at the Advanced Photon Source, he said. “I recommend some of the potential users to perform experiments at the APS first before coming to the HXN.” By the time scientists arrive at his beamline, Chu said he’s gotten to know them through numerous discussions. He considers them “as a guest” at the HXN hotel. “We try to make sure the experimental needs for the users are met as much as possible,” he said.

The HXN beamline has three staff scientists and two postdoctoral fellows who remain in contact with scientists who use the facility. “For most of the users, at least one of us is working throughout the weekends and late evenings,” said Chu.

Not just a staff scientist, Chu is also a user of the HXN, with currently one active general user proposal through a peer review process in which he is collaborating with Stony Brook University and BNL scientist Esther Takeuchi to explore the nanostructure of metal atoms during phase separation in batteries.

Chu and his wife Youngkyu Park, who works at Cold Spring Harbor Laboratory as a research investigator in basic and preclinical cancer research, live in Northport. The couple’s 22-year-old son Luke is attending Nassau Community College and is planning to transfer to Stony Brook this fall to study engineering. Their daughter Joyce is 18 and is enrolled in the Parsons School of Design in New York.

Chu grew up in Seoul, South Korea, and came to the United States when he was 18. He attended Caltech. While Chu’s parents wanted him to become a doctor, he was more inspired by a cartoon called Astro Boy, in which a scientist, Dr. Tenma, is a hero solving problems. As for the work of the scientists who visit his beamline, Chu said the “success of individual users is the success of the beamline.”