By Daniel Dunaief

Leave a bicycle out in the rain for a few weeks and the metal gears and chain will develop rust that reduces the value and usefulness of that once shiny vehicle.

Now, imagine what the inside of a nuclear reactor looks like after high temperatures and ionizing radiation collide with everything they hit.

Chemists at Brookhaven National Laboratory, working with their partners at Idaho National Laboratory, recently showed how reactors cooled by molten salts had less corrosion in the reactor metals.

Molten salt cooled reactors are “intrinsically safe,” said James Wishart, Distinguished Chemist at BNL and director of the Molten Salts in Extreme Environments Energy Frontier Research Center. “They are already molten so they can’t melt down.”

The advantages of molten salt reactors are evident in their safety and their economics. These reactors are also better for the environment and for non proliferation of nuclear material.

That is in contrast to what happened in 2011 after a tsunami hit the Fukushima nuclear plant in Japan, which had a meltdown at three of the plant’s reactors.

Fukushima lost the ability to cool the reactors because the tsunami knocked out the generators. A water reactor type meltdown can’t occur with a molten salt reactor because the fuel is already liquid and the reactor materials contain it in that state.

Chromium studies

In recent research published in the journal Physical Chemistry Chemical Physics, Wishart and his collaborators described the radiation-induced reactors of two ions of chromium, chromium 2+ and chromium 3+.

“Chromium is frequently the easiest metal to corrode from an alloy,” Wishart explained.

When chromium has a positive charge of three, it could be particularly problematic for the structural integrity and performance of the reactor. Chromium with a positive charge of two, on the other hand, may not be as problematic or corrosive to the nuclear reactor materials. Molten salts, which have negative ions of chlorine, can reduce chromium to the less reactive version.

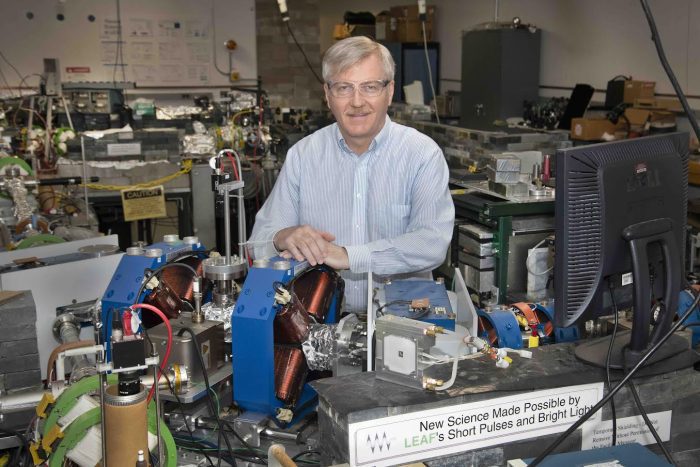

By using the Laser Electron Accelerator Facility (LEAF) and the two-million electron volt Van de Graaff accelerator, Wishart tested the rate and temperature dependencies of reactions of the two chromium ions with reactive species generated by radiation in molten salt.

The solvated electrons and dichloride radicals, both of which have a negative charge, change the oxidation state of chromium to the less corrosive Cr 2+.

Commercial applications

Molten salt reactor research started in the late 1940’s.

In 1972, the Atomic Energy Commission expressed reservations about some technology issues and suggested that the engineering development of large components, a better understanding of the behavior of fission products and adequate remote inspection and maintenance techniques would be needed before molten salt reactors would be suitable for development.

The molten salt reactors were also not high enough on the development priority ranking of the government to have assurance of the required sustained resource allocation, according to an International Atomic Energy Agency Report on the Status of Molten Salt Reactor Technology.

Currently, however, at least a dozen companies are working on generators cooled by molten salts, with some involving chloride and others using fluoride.

Texas Abilene Christian University is building one such reactor, which would be the first university-based molten salt research reactor. The interest in these types of reactors has been growing around the world.

“We are providing information to help [people working in applied areas] understand the chemical transformations that molten salt fuel will undergo due to radiation inside the reactor,” said Wishart.

Several companies, including Thorcon Power and Seaborg Technologies, are also working on designs that can be built into modular forms and shipped by barge wherever power is needed.

In addition to reducing the threat from a melt down, these molten salt reactors also operate at relatively low vapor pressures, which is a “huge benefit in safety and in engineering,” Wishart added.

Molten salts have much lower vapor pressures than water because they are held together by very strong Coulombic forces, which come from the attraction of oppositely-charged ions.

Next studies

While the molten salt reactors favor the creation of a less problematic ionization state of chromium, they also produce other side reactions.

“With time and the large amount of radiation within the reactor, side reactions can lead to permanent products,” Wishart explained.

Studies of molten salt corrosion show a correlation between the presence and quantity of air and water and the rate of corrosion. Salts with low water and air contamination show little corrosion.

Wishart is now looking at more complex salt mixtures than the first series of experiments. Different cations, or positively charged ions, affect the reactivity of solvated electrons. He is investigating how that might divert the electron into side reactions that lead to the accumulation of permanent products.

Ground floor

Wishart was responsible for the construction of LEAF and for its operation for most of its 26-year history. When he and his colleagues were building the facility, he was eager to test out the facility’s ability to follow reactions on fast time scales, at about 10 picoseconds. A picosecond is such a small unit of time that an eye blink, which lasts about 0.1 seconds, is about 100 million picoseconds, so it records reactions rapid reactions.

Wishart was pleasantly surprised by all the scientific questions LEAF could address.

“I only started working on ionic liquids three years after LEAF was completed, so we could not anticipate how LEAF would enable that science to grow and then see it translate into molten salts,” he explained.

Wishart has published 76 papers on the radiation chemistry and/or physical chemistry since he started working on them in 2001.

Originally from the Detroit area, he returns periodically to spend time with family.

Wishart’s interest in chemistry began when he was a photographer for the high school yearbook, which, at the time, was printed in black and white. He made prints using traditional silver-based emulsions and was interested in the chemistry that caused the images to form under development.

When he was a PhD student at Stanford, Wishart mainly studied the chemistry of ruthenium, which is a second-row transition metal in the same family as iron. He found ruthenium satisfying to work with because scientists can watch the colors change to indicate when a reaction is done.