BNL’s Wang conducts ‘pioneering’ battery studies

By Daniel Dunaief

The first time is most definitely not the charm. That’s what Jun Wang and her colleagues at Brookhaven National Laboratory discovered about sodium ion batteries.

Wang, a physicist and lead scientist at the facility, looked deep into the inner workings of a sodium ion battery to determine what causes structural defects as the battery functions. As it turns out, the first time a sodium ion battery charges and discharges, it develops changes in the microstructure and chemical composition of iron sulfide. These changes, which degrade the performance of the battery, are irreversible during the first charging cycle.

“We found that the cracks happened during the first cycle, then, after that, the structure kind of reached equilibrium,” said Wang, who published her research in the journal Advanced Energy Materials. “All these changes happen during the first cycle.”

Sodium ion batteries are considered an alternative to lithium ion batteries, which are typically found in most consumer electronics. Like lithium, sodium is an alkali metal, which means that it is in the same group in the periodic table. Sodium, however, is more abundant and, as a result, considerably less expensive than lithium.

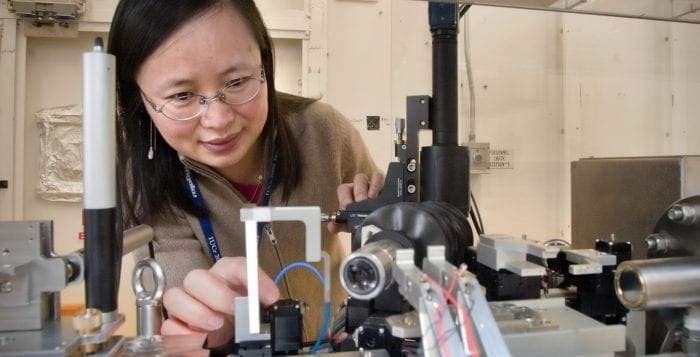

Using a synchrotron-based hard X-ray full-field microscope, Wang was able to see what happened when sodium ions moved into and out of an iron sulfide electrode through 10 cycles. “We can see this microstructure evolution,” she said.

Wang monitored the evolution as a function of time while the battery is charging and discharging. The results are the first time anyone has studied a sodium-metal sulfide battery with these tools, which provides information that isn’t available through other methods. “It is challenging to prepare a working sodium ion battery for the in operandi/in situ TXM study to correlate the microstructural evolution with its electrochemical performance,” she said.

Other researchers suggested that Wang has developed a following in the scientific community for her ground-breaking research. “She has a very good reputation in the area of X-ray nanotomography, applied to a wide range of different materials,” Scott Barnett, a professor of materials science and engineering at Northwestern University, explained in an email. “I am most familiar with her work on fuel cell and battery electrodes — I think it is fair to say that this work has been some of the best pioneering research in this area,” he said.

Barnett, who started collaborating with Wang in 2010 on measuring fuel cell and battery electrodes with X-ray tomography, suggested that Wang’s work on capacity loss “could certainly lead to new breakthroughs in improved batteries.”

In her most recent work with sodium ion batteries, Wang found that the defects start at the surface of the iron sulfide particles and move inward toward the core, Wang said. The microstructure changes during the first cycle and is more severe during sodiation. The particles don’t return to their original volume and shape. After the first cycle, the particles reach a structural equilibrium with no further significant morphological changes, she said.

In other cycles, the material does not show further significant morphological changes, reach a structural equilibrium and electrochemical reversibility. Wang and her colleagues confirmed these observations with X-ray nanotomography, which creates a three-dimensional image of the battery material while recording the change in volume.

Wang suggested that a way to reduce these structural defects could be to reduce the size of the iron sulfide particles to create a one-phase reaction. She will work with other collaborators on modeling and simulations that will enhance the design of future battery materials.

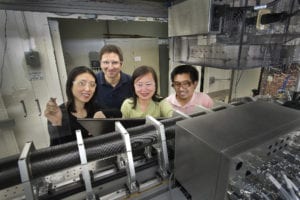

In addition to conducting research on batteries, Wang is an industrial program coordinator in the Photon Science Directorate at BNL. She works with industrial researchers and beamline staff to find and explore new opportunities in industrial applications using synchrotron radiation. She leads the industrial research program, interacting with user groups through consultation, collaboration and outreach.

To manage her research, which includes a lab of three other researchers, and to accomplish her mission as manager of an industrial research program, Wang jokes that she “spends 100 percent of her time” with each responsibility. “I try to do my best for the different things” she needs to do with her time, she said.

A native of Wuhu, China, Wang earned her bachelor’s degree in physics from Anhui University in China and her doctorate in physics from the Chinese Academy of Sciences in Beijing. She worked at the Beijing Synchrotron Radiation Facility, which was the first synchrotron light source in China. During her doctoral training, she studied multilayer films using X-ray diffraction and scattering.

A resident of Poquott, Wang is married to Qun Shen, who is the deputy director for science at the NSLS-II. The couple has an 11-year-old son, Sam, who is a sixth-grade student at Setauket Elementary School. Shen and Wang met at an international X-ray crystallography conference in the early 1990s.

Shen trained in the United States after he graduated from Beijing University in 1980, when he went to Purdue University for his doctorate through the China-US Physica Examination and Application Program. The couple have worked together a few times over the years, including publishing a paper in Nature Communications. Wang is hoping that her work with battery research will lead to improvements in the manufacture and design of sodium ion batteries.